Whirlpool GC1000 Garbage Disposal Not Working – Embarking on a meticulous exploration of the garbage disposal universe necessitates an intrinsic understanding of its foundational premise.

A garbage disposal system, eloquently designed, avails itself as a quintessential ally in the stewardship of culinary spaces, deftly managing residual waste with a semblance of grace and efficacy.

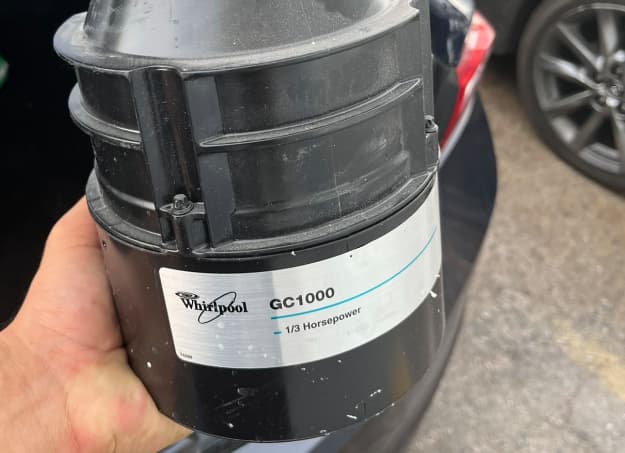

Whirlpool GC1000 Garbage Disposal Not Working

Importance in Modern Kitchen Settings

The role of garbage disposals, especially the Whirlpool GC1000, is vital. This powerful tool helps manage food waste, making kitchen tasks easier and more organized, avoiding any unwanted mess.

Anatomy of the Whirlpool GC1000

Navigating through the operational labyrinth of garbage disposal, particularly one as noteworthy as the Whirlpool GC1000, calls for an immersion into its mechanical and electrical symphony.

- Turn it On: The Synergy of Electrical and Mechanical Operands

When one engages the switch to initiate the Whirlpool GC1000, it summons a cascade of both mechanical and electrical operations. The activation prompts an electrical current to permeate through the unit, invigorating the motor which, in turn, conjures the mechanical actuation of the impellers. This harmonious interplay between electrical and mechanical constituents not only underpins the functionality of the disposal but also substantiates its capability to efficaciously manage waste.

- Grinding: An Odyssey from Solid to Liquid

The act of grinding is an intrinsic feature of the GC1000, wherein food waste undergoes a transformative journey from solid particles to a near-liquid state, thereby averting potential pipe blockages. The grinding chamber, by virtue of its meticulously crafted design and strategically positioned impellers, dissects the incoming food waste, gradually mutating it into a substance amenable to effortless transit through the plumbing infrastructure.

Key Components and Their Functions

Embarking upon an exploration of the Whirlpool GC1000 mandates a detailed acquaintance with its key components, each of which is a pivotal actor in the grand opera of waste disposal.

- Grinding Chamber: The Crucible of Transformation

The grinding chamber can aptly be envisaged as the crucible wherein the metamorphosis of food waste is orchestrated. This chamber, an epitome of engineering prowess, is armored with a ground ring, ensuring that food is methodically disintegrated into a pulverized form, thus ensuring that the subsequent passage through plumbing systems is bereft of obstruction or hindrance.

- Impellers: The Conduits of Movement and Maceration

Positioned within the grinding chamber, the impellers serve as the dynamic force propelling the food against the grind ring. These rotational elements, forged with precision and endurance, serve dual purposes: firstly, they aid in the meticulous maceration of the waste, and secondly, they act as conduits, propelling the processed waste into the drain chamber, thus ensuring a continuum in the waste disposal process.

- Drain Chamber: The Gateway to Expulsion

The drain chamber acts as the terminus of the disposal journey within the unit. Following the rigorous grinding process, the resultant effluent finds itself navigating through the drain chamber. This segment is meticulously engineered to seamlessly integrate with conventional plumbing systems, thus ensuring that the transition of the waste from the disposal unit to the external waste management systems is executed with unerring precision and efficacy.

Common Problems in Garbage Disposal Units

Navigating through the multifaceted issues that might impede the optimally functioning garbage disposal units, especially those as reputable as the Whirlpool GC1000, demands an acute understanding of the prevalent problems and their respective solutions.

Jamming Issues

The occurrence of jamming within the disposal unit often witnessed as a refusal to operate or perplexing sounds, warrants immediate attention.

- Cause: Navigating through the Nuisance of Obstruction

Jamming, particularly in the context of garbage disposals, can be visualized as an unyielding halt in the machinery’s operation, induced by an obstruction within the mechanical components. This situation emerges when objects, either inadvertently or intentionally introduced, besiege the impellers, halting their rotational capacity and, by extension, inhibiting the disposal’s ability to effectuate the grinding of waste.

- Solution: The Liberation of Impellers

Rectifying jamming may necessitate an excursion into the inner workings of the unit, employing a jam-buster wrench as the key to liberating the impellers. This tool, when inserted into the corresponding slot at the base of the unit, facilitates manual rotation of the impellers, potentially dislodging the obstructive elements and reviving the unit’s operationality. Cautiously turning the wrench back and forth may, with persistence, resolve the jam, rendering the unit ready to resume its waste disposal duties.

Leaking and Drainage Concerns

Leaks, discernible through puddles or dampness beneath the unit, introduce both hygienic and operational dilemmas that necessitate swift redress.

- Identifying Leaks: The Pursuit of Unwanted Moisture

The initiation of leak troubleshooting pivots upon the identification of unwarranted moisture beneath the unit. A methodical visual inspection, exploring the unit and adjacent plumbing, seeks to discern the origin of this undesirable seepage, which may manifest as pools of water, damp surfaces, or even localized corrosion on the unit or connected pipework.

- Solving Leaks: The Odyssey Towards a Dry Equilibrium

Once leaks have been identified, an odyssey towards restoration commences, wherein the user, equipped with an arsenal of wrenches and replacement gaskets or seals, endeavors to halt the permeation of water. Solutions may range from the mere tightening of connections, fortifying the barrier against leaks, to the replacement of compromised seals, ensuring that every juncture within the unit is impervious to unwanted fluid escape.

Investigating the GC1000 Malfunctions

Identifying Symptomatic Behavior

- Listening: Strange noises can indicate an issue.

- Watching: If it doesn’t start, there might be a problem.

Preliminary Diagnosis Techniques

- Checking Visually: A simple visual check might show obvious issues.

- Testing Elements: Use a multimeter for checking electrical faults.

In-depth Analysis of Specific Issues

Electrical and Power Challenges

- Checking Connections: Ensure wires and plugs are properly connected.

- Fuse and Breaker: Ensure fuses aren’t blown and breakers aren’t tripped.

Mechanical Complications

- Look Inside: Ensure no spoons or non-food items are inside.

- Check Movement: Ensure impellers are moving freely.

Safety Protocols in Troubleshooting

Precautionary Measures

- Power Off: Always disconnect power before troubleshooting.

- Use Gloves: Protect your hands with gloves.

Essential Tools and Equipment

- Have a Wrench: For loosening and tightening parts.

- Pliers: To grip and turn parts.

Methodical Troubleshooting

Electrical Issue Resolution

- Identifying Problem: Use a multimeter to check for continuity.

- Fixing Wires: Replace or repair damaged wires.

Mechanical Failure Solutions

- Free Impellers: Ensure nothing obstructs the impellers.

- Replace if Needed: Sometimes parts may need replacement.

Professional Insights into Repair and Maintenance

Scheduled Maintenance Practices

- Regular Checks: Visually inspect for wear and tear.

- Clean Regularly: Use a mixture of ice and salt for cleaning.

Employing Professional Repair Services

- For Complex Issues: Hire a professional if issues are too complex.

- Warranty: Ensure hiring a professional doesn’t void the warranty.

Effective Use and Care Tips

Routine Care Instructions

- Regular Cleaning: Weekly cleanings can prevent build-ups.

- Run Regularly: Ensure to run it regularly to avoid rust and corrosion.

Prohibitions and Best Practices

- Avoid Certain Items: No fats, oils, or non-food items.

- Cold Water: Always use cold water to avoid melting fats.

This guide hopes to navigate through the essentials of managing and maintaining the Whirlpool GC1000 garbage disposal, from understanding its components to addressing common issues and practicing robust care habits. Remember, safety first, and when in doubt, consult a professional technician.

More Related Guides:

- Whirlpool Microwave Fan Won’t Turn Off SPD2

- Whirlpool Dishwasher Fills with Water Then Stops

- Whirlpool Cabrio Dryer Reset

Final Thoughts:

In the realm of waste management, the humble garbage disposal emerges as a silent sentinel, tirelessly facilitating culinary hygiene and efficiency, meriting both our understanding and conscientious stewardship to preserve its invaluable service.

Note: Always ensure to follow all safety guidelines and when in doubt, consult with a professional before attempting to fix any electrical appliances or you can say the whirlpool gc1000 garbage disposal not working, such garbage disposals, to avoid injury or damage to the unit.